Quanser's unmanned technology got a lot of attention this summer. Delegates at the ASEE Annual Conference, ACC 2010 and AIAA Guidance, Navigation and Control Conference had an opportunity to experience the Unmanned Vehicle Systems Lab and fly Quanser's Qball-X4, an unmanned aerial vehicle. Students and professors asked our engineers many great questions about applications, sensors, cameras and batteries. We captured the technical questions and summarized answers for you. What is the payload of the Qball-X4? The Qball-X4 can carry up to a maximum of 400 g,  but since more weight reduces flight time, we recommend payloads of 300 g or less. This is an important consideration when adding sensors to the Qball.

but since more weight reduces flight time, we recommend payloads of 300 g or less. This is an important consideration when adding sensors to the Qball.

What kind of sensors come on the Qball-X4? The main sensors on the Qball-X4 are:

- 3-axis gyroscope

- 3-axis accelerometer

- 3-axis magnetometer

- Pressure sensor

These on-board sensors are used to primarily stabilize the vehicle. In addition, they can be used for obstacle avoidance missions.

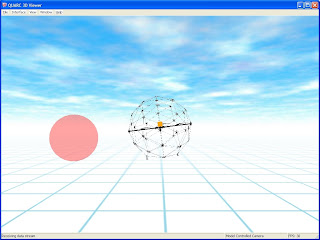

What are the OptiTrack™ cameras for? The OptiTrack cameras are for tracking the  position (XYZ) of the vehicles (multiple vehicles if desired) in the lab workspace. They function as indoor GPS but with much higher sampling rates (up to 100 fps) and much higher accuracy (on the order of 1 cm or less). The cameras are not strictly necessary to fly the Qball-X4, but are an integral component of the lab. These cameras are important for performing autonomous missions as they provide the position feedback (XYZ) that is not measurable by the Qball-X4’s on-board sensors directly.

position (XYZ) of the vehicles (multiple vehicles if desired) in the lab workspace. They function as indoor GPS but with much higher sampling rates (up to 100 fps) and much higher accuracy (on the order of 1 cm or less). The cameras are not strictly necessary to fly the Qball-X4, but are an integral component of the lab. These cameras are important for performing autonomous missions as they provide the position feedback (XYZ) that is not measurable by the Qball-X4’s on-board sensors directly.

Can I mount the OptiTrack cameras on the Qball-X4 or another vehicle? The cameras must be mounted in fixed positions in your lab space and calibrated. They should not be placed on the Qball-X4 or Qbot vehicles.

Can I use different cameras? Since the system is modular, it is easy to swap out the OptiTrack cameras for another localization system provided the new system is interfaceable to Simulink®. Quanser’s technology also supports VICON cameras.

What kind of batteries are used on the Qball-X4? How long can the Qball-X4 fly? We use two LiPo (Lithium Polymer) batteries on each Qball-X4, which allows up to 15 minutes of continuous flight. The full battery recharge for the next flight takes app. 45-60 min. Each Qball-X4 is supplied with a spare set of batteries and a recharger.

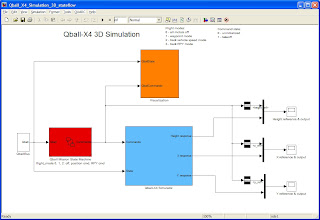

Can the UVS Lab be used to run multiple vehicles simultaneously and how do they communicate? Yes, the UVS Lab is designed to run  multi-vehicle missions simultaneously. Since each vehicle is equipped with its own embedded Gumstix® and HiQ DAQ, multiple vehicles can be deployed using WiFi. Due to the nature of Simulink, a controller (Simulink model) can only be run on one target (Qball-X4) at any given time. Thus, to run multiple vehicles, multiple Simulink models have to be created and each model needs to be targeted to a specific vehicle. The on-board Gumstix computer is equipped with WiFi 802.11g and the QUARC software included with the UVS Lab allows to communicate wirelessly (TCP/IP or UDP) between vehicles.

multi-vehicle missions simultaneously. Since each vehicle is equipped with its own embedded Gumstix® and HiQ DAQ, multiple vehicles can be deployed using WiFi. Due to the nature of Simulink, a controller (Simulink model) can only be run on one target (Qball-X4) at any given time. Thus, to run multiple vehicles, multiple Simulink models have to be created and each model needs to be targeted to a specific vehicle. The on-board Gumstix computer is equipped with WiFi 802.11g and the QUARC software included with the UVS Lab allows to communicate wirelessly (TCP/IP or UDP) between vehicles.

Can I add my own sensors to the Qball-X4? What kind of I/O is available on the Qball-X4? The Qball-X4 DAQ, the HiQ, was designed with additional I/O ports so that other sensors can be easily integrated into the system. Some of the I/O available on the HiQ for use with other sensors are:

- 6 analog inputs

- 11 reconfigurable digital I/O

- 2 general purpose TTL serial ports

The pins are found on the HiQ daughterboard. Once a sensor is connected, these inputs can be read in Simulink using the QUARC HIL blocksets and Stream API. The main consideration for adding additional sensors is whether they:

- meet payload requirements

- meet the particular I/O voltage and current requirements.

Can I add a camera to the Qball-X4? Is the Qball-X4 capable of performing image processing? The on-board computer is a 600 mHz Gumstix Verdex with 128 MB of RAM. The computer is designed for low weight, low power consumption and small form factor. It does not have the processing capability to perform significant image processing (greater than 10 fps). The recommended solution for image processing is to use a wireless camera that can stream video to a more powerful ground station computer, which can process the video and stream back the results to the controller (i.e. Gumstix) over WiFi. Can the on-board Gumstix be replaced with a more powerful embedded computer? The HiQ is designed to interface specifically with the Gumstix Verdex computer and the UVS Lab software QUARC supports only this model of Gumstix. As embedded computer technology evolves, it is likely this lab will support more powerful embedded computers.

Is the Qball-X4 an off-the-shelf helicopter or is it made by Quanser? The Qball-X4 is a helicopter designed and manufactured by Quanser. The HiQ, a high-end DAQ is also designed by Quanser and customized for UVS research.

How much does the UVS Lab cost? Can I buy just the Qball-X4 or do I need to purchase the entire setup? For pricing, please contact our Academic Solutions Advisors at info@quanser.com. You have an option to purchase Qball-X4 or Qbot (unmanned ground vehicle) separately or as a turn-key lab. You can also purchase multiple unmanned vehicles for your lab.

For details on the UVS Lab components, please refer to the Product Information Sheet.

For a UVS Lab demonstration, please contact Sunny Ray at sunny.ray@quanser.com

Several Canadian companies mentioned in a recent

Several Canadian companies mentioned in a recent